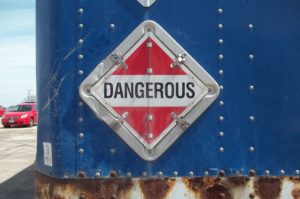

All shipments of a hazardous material (HazMat) must comply with the regulations of 49 CFR 173.24 known as the General Packing Requirements. Therefore, if you are the shipper of a HazMat – even one subject to an exception from regulation – you must comply with the General Packing Requirements. The purpose of this article is to identify and explain all of the responsibilities of a shipper of HazMat in §173.24 of the PHMSA/USDOT Hazardous Materials Regulations (HMR).

Applicability:

Unless specifically indicated elsewhere the General Packing Requirements apply to all packagings:

- Bulk and non-bulk.

- §173.24a contains additional packing requirements for non-bulk packagings.

- §173.24b contains additional packing requirements for bulk packagings.

Read: What is a Bulk Packaging?

- New and reused.

- Specification and non-specification.

Common Sense Stuff:

Each package used for the shipment of HazMat must be designed, constructed, maintained, filled – not overfilled – and closed so none of the following occurs under normal transportation conditions.

- A release of HazMat to the environment that can be detected by unaided human senses. Detection through the use of instruments doesn’t count.

- Damage to the packaging due to any of the following:

- Minimum and maximum temperature.

- Changes in humidity and pressure.

- Shocks, loadings, and vibrations.

- A mixture of gases or vapors in the package that could damage the packaging.

- A residue of a HazMat adheres to the outside of the packaging.

| Note: As the shipper of the HazMat you are required to know the conditions to be expected during normal transport. To include but not be limited to: temperature, pressure, vibrations, exposure to elements, handling, &etc. |

Authorized Packagings (two options):

Option 1. The packaging is authorized for the HazMat by the standard method:

- Prescribed in the section of part 173 identified in column 8 of the Hazardous Materials Table. And…

- Conforms to the applicable requirements of the special provision codes in column 7 of the Hazardous Materials Table. And…

- The specification requirements of part 178 (for all packagings except rail tank cars) or part 179 (tank cars).

| Note: This does not apply to a UN standard packaging manufactured outside the U.S. For more on that, read the next section: Specification Packaging. |

Option 2. The packaging is permitted under and conforms to:

- Provisions contained in 49 CFR 171, subpart B or C:

- Subpart B regarding an approval or authorization issued by the Bureau of Explosives.

- Subpart C regarding the international transportation regulations of the ICAO Technical Instructions, the IMDG Code, Transport Canada TDG Regulations, or the IAEA Regulations.

Or…

- §173.3 regarding salvage packagings

- §173.4 regarding the small quantity exception

- §173.4a regarding the excepted quantity exception

- §173.4b regarding the de minimis exception

- §173.5 regarding agricultural operations

- §173.5a regarding oilfield service vehicles, mechanical displacement meter provers, and roadway striping vehicle exceptions

- §173.6 regarding the materials of trade exception

- §173.7 regarding government operations and materials

- §173.8 regarding exceptions for non-specification packagings used in intrastate transportation

- §173.27 regarding the general requirements for transportation by aircraft

- §176.11 regarding exceptions for transportation of HazMat by vessel

Read: Determining Authorized Packaging for the Transportation of a Hazardous Material

And one more thing…

The use of supplementary packagings within an outer packaging additional to what is required by these regulations is permitted provided all applicable requirements of the regulations are met and, when necessary, suitable cushioning is used to prevent movement within the packaging.

Example: A 55-gallon steel drum is the authorized packaging for a hazardous material. The HazMat is currently contained in a 30-gallon fiber drum that is in good condition but is not authorized. The 30-gallon non-authorized packaging may be placed in the 55-gallon authorized packaging as long as all other applicable requirements of the Hazardous Materials Regulations are met and cushioning is used to prevent movement of the 30-gallon drum inside the 55-gallon drum.

Specification Packagings and UN Standard Packagings Manufactured Outside the U.S.:

A specification packaging – including a UN standard packaging – manufactured in the U.S. must conform to the applicable specification or standard in part 178 (for all packagings except rail tank cars) or part 179 (tank cars).

A UN standard packaging manufactured outside the U.S. may be imported and used and is considered to be an authorized packaging subject to the the following conditions and limitations:

- It was manufactured in accordance with national or international regulations that are based on the UN Recommendations. Just like the PHMSA/USDOT regulations are based on the UN Recommendations.

- The packaging fully conforms to the UN Recommendations and the requirements of 49 CFR 173, subpart B, including the reuse provisions.

- The packaging is capable of passing the prescribed tests for its type of packaging in part 178.

- The competent authority of the country of manufacture provides reciprocal treatment for UN standard packagings manufactured in the U.S.

Compatibility:

- No matter what packagings are prescribed for a HazMat by part 173, it is the responsibility of the shipper to ensure the packaging is compatible with its contents. This particularly applies to the following:

- Corrosivity

- Permeability

- Softening

- Premature aging

- Embrittlement

- There must be no significant chemical or galvanic reaction between the HazMat and the packaging.

- Plastic packagings and receptacles (i.e. inner packagings of a combination packaging) must be compatible with the HazMat and must not be so permeable that a hazardous condition may occur. Each plastic packaging used for liquid HazMat must be capable of withstanding the test of its chemical compatibility and rate of permeation in the test procedure specified in appendix B of part 173 (Procedure for Testing Chemical Compatibility and Rate of Permeation in Plastic Packagings and Receptacles). Alternative test procedures or rates of permeation are permitted if as safe as the standard and if approved by PHMSA/USDOT. There’s more – a lot more – you can read it yourself at 49 CFR 173.24(e)(3)(ii-iii).

- HazMat may not be packed or mixed together in the same outer packaging with other HazMat or even non-HazMat if a combination could cause any of the following:

- Combustion or dangerous release of heat.

- Release of flammable, poisonous, or asphyxiant gases.

- Formation of unstable or corrosive materials

- If a solid HazMat may become liquid during transportation the packaging must be able to contain it in its liquid form.

Closures:

Closures:

Closures on packagings must be designed (responsibility of the packaging manufacturer) and closed (responsibility of the shipper) so that under normal transportation conditions…

- There is no identifiable release to the environment from the opening unless it is ‘venting’ allowed by §173.24(g) (see next section).

- The closure is leakproof and secured against loosening. For air transport, closures held in place by friction (e.g. stoppers, corks) must also be held in place by some positive means.

| Note: Transportation of HazMat by air will likely be subject to the dangerous goods regulations of ICAO/IATA which are more strict than those of PHMSA/USDOT described here. |

Unless indicated otherwise, a packaging closure – and closure components such as gaskets – of a specification packaging must meet all the requirements of the specification (responsibility of the packaging manufacturer) and be closed (responsibility of the shipper) in accordance with instructions provided by the manufacturer. This means that closure components used for a specification packaging must be those specified in the closure instructions (LOI 15-0144).

Venting:

Venting of a packaging is permitted only under the following conditions:

- Its purpose is to reduce internal pressure that may develop due to the creation of gas from the contents.

- Transportation by aircraft is not allowed unless HazMat is one of the following:

- A cryogenic liquid as specified at §1732.320(c).

- Carbon dioxide, solid (dry ice).

- The gases created under normal transportation conditions are not one of the following:

- Poisonous

- Likely to create a flammable mixture with air.

- An asphyxiant.

| Note: An asphyxiant is a substance that can cause unconsciousness or death by suffocation (asphyxiation). |

- The packaging is designed to prevent an unintentional release of HazMat. An unintentional release is distinct from the gas released through the packaging’s permitted venting which is intentional.

Outage and filling limits:

These regulations (49 CFR 173.24) do not include specific outage (aka: ullage) and filling limits for packagings containing HazMat. It does include the following:

- A general requirement that packagings and receptacles for liquids must be filled to leave sufficient outage to allow for expansion due to likely transportation temperatures.

- A reference to specific outage and filling limits elsewhere in the HMR:

- §173.24a(d) for liquids in non-bulk packaging.

- §173.24b(a) for bulk packaging.

- §173.301 through §173.306 for compressed gases and cryogenic liquids in cylinders.

- §173.314 through §173.319 for compressed gases and cryogenic liquids in bulk packagings.

| Note: Only at §173.24b(a) applicable to a bulk packaging does the possibility exist of an outage or filling limit applicable to a solid HazMat. All other limits are applicable solely to a liquid or gas. |

Air transportation:

Except for packages subject to the following regulations, all packages for transport by air must conform to the general requirements for transportation by aircraft at §173.27. The exception to this requirement are the HazMat subject to or identified in the following:

- A restriction or limitation for a specific HazMat identified at §171, subpart C – Authorization and Requirements for the Use of International Transport Standards and Regulations.

- A consumer commodity packaged pursuant to 49 CFR 173.167 of the HMR.

- A consumer commodity packaged pursuant to Packing Instruction Y963 of the ICAO Technical Instructions or the IATA dangerous goods regulations.

If you like this article, please share it using any of the social media platforms identified at the bottom of this article. You’ll look real smart recommending my articles! |

Conclusion:

Remember: these are only the general packing requirements applicable to all packagings and all modes of transport. There are also the following additional general packing requirements:

- §173.24a – Additional general requirements for non-bulk packagings and packages

- §173.24b – Additional general requirements for bulk packagings

- §173.27 – General requirements for transportation by aircraft

And then there are the packing instructions specific to the HazMat classification (e.g. §173.185 for lithium cells and batteries).

Make certain you have thoroughly researched the regulations applicable to your shipment (hazardous material, packaging, mode of transportation…) before you offer for transportation a hazardous material.

Question: Can minor rips, tears, and pinholes be repaired by placing clear adhesive tape over the minor damage as long as this practice does not compromise the packaging’s ability to pass the applicable design qualification test or to provide appropriate containment of the hazardous materials under normal conditions of transportation?

Answer: No, See Q2 of LOI 15-0144.

Question: Can a carrier reject a packaging for transport if the shipper complies with all of 49 CFR 173.24 and all other applicable requirements of the HMR?

Answer: Yes. See second from final line of LOI 15-0144.

The general packing requirements of part 173 aren’t the end of it. As as matter of fact, they are only the beginning. A shipper of HazMat still has a long way to go to ensure their HazMat is classified, described, packaged, marked and labeled/placarded, and are in all respects in proper condition for transport. Please continue to read my articles to learn more. Subscribe to my newsletter so you’ll not miss anything. And be sure to contact me with any questions.