A generator of hazardous waste must conduct a hazardous waste determination for all solid waste it generates. This requirement is codified in federal regulations at 40 CFR 262.11. A solid waste is defined and explained at 40 CFR 261.2, but for the purposes of this article you may think of a solid waste as any discarded solid, liquid, semi-solid, or containerized gas; pretty much anything you throw away.

The Generator Improvements Rule went into effect on May 30, 2017 in the federal regulations of the U.S. Environmental Protection Agency (USEPA) and in those states that lack an authorized hazardous waste program. Since that date, states with an authorized hazardous waste program have the option of adopting all of the 60+ changes to the generator regulations or only those that are more stringent than existing regulations.

Since all of the revisions made by the Generator Improvements Rule to the regulations of the hazardous waste determination are more stringent than existing regulations, every state must either adopt these revisions or create its own that are even more stringent. This article will address the hazardous waste determination as revised by the Generator Improvements Rule found at 40 CFR 262.11 of the USEPA regulations.

Introduction:

A person who generates a solid waste must make an accurate determination as to whether it is a hazardous waste. This determination must be made using the steps specified in §262.11.

- A “person” as that term is used by USEPA – and is defined at §260.10 – includes an individual, a business, or branch of government. This means that every hazardous waste generator – no matter its status – must complete the hazardous waste determination.

- The determination is the sole responsibility of the generator of the waste. Though it may be made by someone else: broker, consultant, transporter or TSDF, in the end it is the generator who will be held responsible for making an accurate determination.

Generators are, and always have been, ultimately responsible for making accurate hazardous waste determinations. (November 28, 2018; 81 FR 85750)

And…

A generator’s failure to properly analyze, label, and accumulate waste does not exempt the waste from regulation. (RO 11424).

- The Generator Improvements Rule codified the requirement that a generator make an “accurate” determination. In other words, you must get it right.

- While the regulations prior to the Generator Improvements Rule required the generator to conduct the hazardous waste determination using a specified “method”, the revised regulations require the generator to follow specified “steps”. This change to one word puts a stronger emphasis on the generator responsibility to follow through precisely as required by USEPA to conduct the hazardous waste determination.

Q: I’m a very small quantity generator of hazardous waste or VSQG (known as a conditionally exempt small quantity generator or CESQG prior to the Generator Improvements Rule). I don’t have to complete the hazardous waste determination, right?

A: Wrong. One of the conditions for exemption of a VSQG found at §262.14(a)(2) is that it “…complies with §262.11(a) through (d).” This takes the VSQG all the way through the hazardous waste determination but stops short of paragraphs (e), (f), & (g) which are explained below.

“Accurate”?

The addition of the word accurate to §262.11, though a small change, has a significant impact and is worth further explanation.

Definition of accurate

1 : free from error especially as the result of care

an accurate diagnosis

2 : conforming exactly to truth or to a standard : EXACT

providing accurate color

3 : able to give an accurate result

an accurate gauge

4 : going to, reaching, or hitting the intended target : not missing the target

an accurate shot/kick

- The revised text indicates an accurate hazardous waste determination must be made, “in order to ensure wastes are properly managed according to applicable RCRA regulations.” In other words, the purpose of an accurate determination is to make certain the waste (hazardous or non-hazardous) is managed in compliance with the regulations.

- The use of “accurate” in §262.11 and its absence elsewhere in the regulations is not meant to imply that other compliance activities can be inaccurate.

- The inclusion of the language, “in order to ensure wastes are properly managed according to applicable RCRA regulations.” allows for the over-management of a waste. In other words, a generator may choose to manage their non-hazardous waste as a hazardous waste in order to ensure, beyond a doubt, proper and protective management of the waste.

“Steps”?

A hazardous waste determination must be made at the point of generation and continue throughout its management. It must be made by the generator using the following steps in this sequence:

- Determine the point of generation for the solid waste.

- Determine if the solid waste is excluded from regulation at §261.4.

- If not excluded, determine if it is a listed hazardous waste per §261, subpart D.

- Then, determine if it is a characteristic hazardous waste per §261, subpart C.

- Maintain a record of the hazardous waste determination.

- Identify all applicable hazardous codes prior to shipping the waste off-site.

- Notice that this is the hazardous waste determination and not a solid waste determination. In fact, the regulations at §262.11 don’t explicitely direct a hazardous waste generator to identify the generation of a solid waste. However, the opening language of the regulation reads: “A person who generates a solid waste, as defined in 40 CFR 261.2…” So, it is necessary to identify the generation of a solid waste before you can determine the presence of a hazardous waste. Also, as noted below, the hazardous waste determination must begin at the point of generation, which is the moment a material is discarded and becomes a solid waste.

When must the hazardous waste determination be made?

Though a long-standing policy and position of the USEPA that a hazardous waste determination be made at the point of generation, the Generator Improvements Rule codified this language at §262.11(a).

- Hazardous waste determination must be made at the point of generation before any dilution, mixing, or other alteration that may change the waste. Point of generation includes both the time and place the waste was first generated (81 FR 85750).

- It is critical, therefore, that the generator determine the exact point of generation of the waste. Any dilution, mixing, or alteration of the waste after this point may be regulated as treatment.

- The determination must continue throughout the cradle-to-grave management of the waste. That requires the generator to know the qualities of its waste, the conditions it will face during management, and to anticipate the changes it may undergo. For example, a solution of a non-hazardous waste may – over time – separate into two or more phases, one of which may display a characteristic of a hazardous waste.

Excluded from regulation? Really?

USEPA regulations include many exclusions from regulation. §262.11(b) now mandates that the generator determine if any of them apply to its waste. If the generator can meet the conditions of one of these exclusions the solid waste may not be a hazardous waste or – even better – it may not be a solid waste at all and remain a material. If any of these exclusions apply – and the generator chooses to utilize it – the hazardous waste determination will end right there.

- 40 CFR 261.4 includes the following exclusions from regulation:

- The generator must determine if exclusions apply. It is not an option. However, the generator is not required to utilize an applicable exclusion.

- If it has an authorized hazardous waste program, a state may not recognize all of the USEPA exclusions from regulation at §261.4.

Interested in site specific training at your site that covers this topic, and more! Ask me about my Onsite Training |

But what if the solid waste is not excluded at 40 CFR 261.4?

If not excluded at §261.4, the generator must then use their knowledge of the waste to determine if it is a listed hazardous waste. At §262.11(c) the new regulations of the Generator Improvements Rule mandate that solely generator knowledge be used to identify a listed hazardous waste. It also identified what is acceptable to use as knowledge.

- The four (4) types of listed hazardous waste regulated by USEPA are identified at §261, subpart D.

- Acceptable knowledge for completing this step of the hazardous waste determination may include:

- Waste origin

- Waste composition

- The process producing the waste

- Feedstock

- Other reliable and relevant information

- If it has an authorized hazardous waste program, your state may identify and regulate listed hazardous waste in addition to those of the USEPA.

- The determination of a listed hazardous waste is based solely on generator knowledge. It does not require the testing of a representative sample.

- If listed, a generator may submit a de-listing petition to USEPA or its state per §260.20 & §260.22 to demonstrate the waste is not a hazardous waste.

That takes care of listed hazardous waste. What about characteristic hazardous waste?

The generator must also determine if the waste exhibits one or more hazardous characteristics using either generator knowledge, testing of a representative sample if knowledge is inadequate, or a combination of both. This represents a change from the original regulations at §262.11(c) which required the use of either testing or knowledge to determine the characteristic, but not both. These regulations are now found at §262.11(d) and divided into two paragraphs: (1) for the use of knowledge and (2) for the testing of a representative sample.

- The four (4) types of characteristic hazardous waste regulated by USEPA are identified at §261, subpart C.

- The determination of hazardous waste characteristics is required whether or not the waste was earlier (at §262.11(c)) identified as a listed hazardous waste.

- The determination of a characteristic hazardous waste must first be made using knowledge of the waste. If that knowledge is inadequate to make an accurate determination the generator must then test a representative sample. However, if knowledge is adequate to make an accurate determination the testing of a representative sample is not required.

- For the purposes of this step of the determination, acceptable knowledge may include:

- Process knowledge (e.g., information about chemical feedstocks and other inputs to the production process).

- Knowledge of products, by-products, and intermediates produced by the manufacturing process.

- Chemical or physical characterization of wastes.

- Information on the chemical and physical properties of the chemicals used or produced by the process or otherwise contained in the waste.

- Testing that shows the properties of the waste.

- Other reliable and relevant information about the properties of the waste or its constituents.

Testing of a representative sample of the waste by other than an approved method (found at §261, subpart C) or an equivalent test method approved by USEPA per §260.21, may be done and considered as generator knowledge. However, such unapproved tests do not, by themselves, provide definitive results.

Testing of a representative sample of the waste by other than an approved method (found at §261, subpart C) or an equivalent test method approved by USEPA per §260.21, may be done and considered as generator knowledge. However, such unapproved tests do not, by themselves, provide definitive results.- When available knowledge is inadequate to accurately determine if a waste displays the characteristic of a hazardous waste, the generator must do the following:

- Obtain a representative sample of the waste as that term is defined at §260.10.

- Test the sample according to the applicable methods of §261, subpart C or an equivalent method approved by USEPA per §260.21.

- The results of a test properly performed per the requirements of §261, subpart C (but not §260.21) are definitive for the purposes of determining a hazardous waste characteristic.

What if the determination reveals a hazardous waste?

If the waste is determined to be hazardous the generator must refer to the specified parts of Title 40 for other possible exclusions or restrictions specific to the waste.

- The specified parts are as follows:

- 261 – Identification and listing of hazardous waste

- 264 – Standards for owners and operators of treatment, storage, and disposal facilities

- 265 – Interim standards for owners and operators of treatment, storage, and disposal facilities

- 266 – Standards for the management of specific hazardous waste and specific types of hazardous waste management facilities

- 267 – Standards for owners and operators of hazardous waste facilities operating under a standardized permit

- 268 – Land disposal restrictions

- 273 – Standards for universal waste management

- But, where’s the used oil? A material meeting the definition of used oil is subject to regulation at §279 and not those for a hazardous waste generator. The generator of a used oil is not subject to the hazardous waste determination. (RO 14054)

- This paragraph of these regulations is unchanged from its form before the Generator Improvements Rule, though its citation has changed (it used to be at §262.11(d)).

Recordkeeping:

Created entirely new by the Generator Improvements Rule, this paragraph at §262.11(f) details the applicability of and requirements for maintaining records of the hazardous waste determination. A small or large quantity generator must maintain records supporting its hazardous waste determinations, including records that identify whether a solid waste is a hazardous waste.

- Prior to the Generator Improvements Rule the requirement for maintaining records of a hazardous waste determination was located at §262.40(c). It was moved to §262.11 to highlight the importance of the recordkeeping requirement to the hazardous waste determination. A reference to §262.11(f) remains at §262.40(c).

- Though proposed, the Generator Improvements Rule did not finalize a requirement for generators to maintain records of their non-hazardous waste determination; though it is recommended as a best management practice. So, if an accurate hazardous waste determination results in the determination of a non-hazardous waste, the generator is not required to maintain a record of that determination. However, some states may be more stringent than federal regulations and may therefore require a generator to maintain records of a non-hazardous waste determination.

Q: Does an inspector have the authority to ask for a hazardous waste determination be performed – or a record of one be provided – for a non-hazardous waste?

A: Yes. “When situations warrant, inspectors have the authority to ask that a hazardous waste determination be performed by the generator in the absence of any documentation and the attributes of the waste suggest a potential problem.” (81 FR 85754)

- Records of a hazardous waste determination must be maintained for at least three (3) years from the date the waste was last sent to on-site or off-site treatment, storage, or disposal. Of course, record retention is extended automatically during an enforcement action or as requested by USEPA.

- The records must comprise the generator’s knowledge of the waste and support the generator’s determination of the waste as either a listed or characteristic hazardous waste.

- The records must include, but are not limited to, the following types of information:

- The results of any tests, sampling, waste analyses, or other determinations made for the hazardous waste determination.

- Records documenting the tests, sampling, and analytical methods used to demonstrate the validity and relevance of such tests.

- Records consulted in order to determine the process by which the waste was generated, the composition of the waste, and the properties of the waste.

- Records which explain the knowledge basis for the generator’s determination of a hazardous waste characteristic.

If you like this article, please share it using any of the social media platforms identified at the bottom of this article. You’ll look real smart sharing my articles! |

Hazardous waste codes:

Also new thanks to the Generator Improvements Rule, §262.11(g) requires the generator (small and large quantity generator only) to identify all USEPA hazardous waste codes (aka: hazardous waste numbers) applicable to the waste.

- Of course, this step need only be taken if the waste is determined to be a hazardous waste since only a hazardous waste has hazardous waste codes.

- The generator must identify all applicable hazardous waste codes prior to offering the hazardous waste for off-site transportation. It is not necessary to identify waste codes at the point of generation. However, SQGs and LQGs may have waste management practices in place and choose to identify the RCRA waste codes sooner than prior to off-site shipment.

- Federal hazardous waste codes are identified in subpart C and D of part 261.

- A state may have waste codes in addition to those of the USEPA. In that case state regulations will require their identification as well.

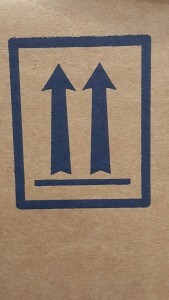

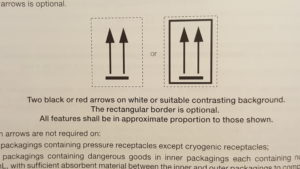

- As part of the pre-transport requirements of §262.32, a small quantity generator and large quantity generator must mark its containers with all applicable hazardous waste codes prior to offering for off-site transportation. Read: Marking of a Hazardous Waste Container for Off-Site Transportation.

- The very small quantity generator is not required to identify the hazardous waste codes applicable to its hazardous waste.

Done!

Remember, the hazardous waste determination is only the first step of your responsibilities as a hazardous waste generator. After you have completed the hazardous waste determination you must count your hazardous waste generation and determine your hazardous waste generator status (both of these regulations were also changed by the Generator Improvements Rule, but that’s an article for a later date).