Before we begin…

- IBC is an intermediate bulk container.

- Hazard communication on an IBC can be complex and includes several options. One option is to display the hazard communication (labels and marks) on the IBC in the same manner as on a non-bulk packaging. Read: HazMat Labels, Markings, and Placards on an Intermediate Bulk Container

- The USDOT/PHMSA Hazardous Materials Regulations identify three situations when a HazMat’s identification number must be displayed on a transport vehicle.

- The transport vehicle itself is a bulk packaging (e.g., cargo tank, rail tank car).

- The transport vehicle contains a bulk packaging (e.g., IBC) and the identification number is not visible. Read: Q&A: Does a bulk packaging require the display of the HazMat’s identification number on the vehicle?

- The transport vehicle contains a large amount of a single HazMat in a non-bulk packaging. Read: Vehicle Marking Requirements for Large Quantities of a Single Hazardous Materials in Non-Bulk Packagings

Question:

If I opt to label an IBC as opposed to placard, and I mark in accordance with 49 CFR 172.301(a)(1), am I still required to display the UN ID marking on the outside of the transport unit as in §172.331(c)?

Answer:

Thank you for contacting me. Please see below.

- Yes.

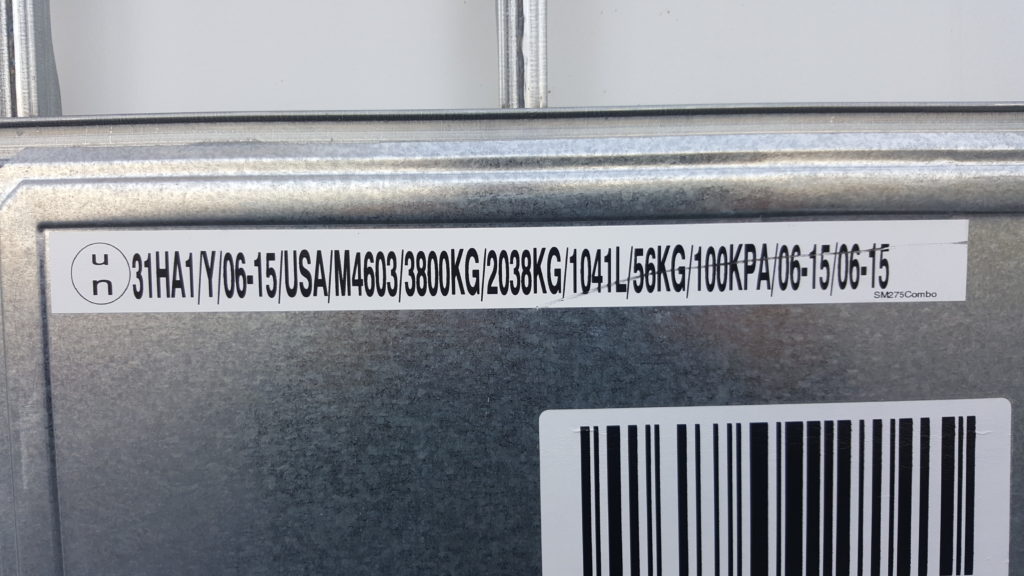

- 49 CFR 172.331(c) refers to the ID # on a bulk packaging. If the ID # on the bulk packaging is not visible when it is in or on the transport vehicle or freight container, then the ID # must be displayed on all four sides of the vehicle or freight container and be visible from the direction it faces.

- The reference to §172.302(a) instead of §172.301(a)(1) may be confusing, but it is at §172.302(a) where the requirement to display the ID # on a bulk packaging is found along with, “except as otherwise provided in this subpart…” which opens the door for hazard communication as described at §172.301(a)(1).

- In the end, the IBC remains a bulk packaging and §172.331(c) is still applicable.

I hope this helps. Please contact me with any other questions.

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services, Inc. 815.821.1550 |

Follow-up and confirm:

I understand. So regardless of how the IBC was actually marked (labeled instead of placarded for instance) the marking is still not visible from the outside, and thus §172.331(c) applies.

Got it. Appreciate the insights!

Final answer:

That is correct!