I saw this truck while negotiating through Chicago-area highway traffic. Luckily I had an assistant riding shotgun to take these few photos. I was at first intrigued by the combination of a Division 4.1 Flammable Solid placard and a HOT marking both on a cargo tank motor vehicle. “What is on that truck?” I thought. Some research into the Hazardous Materials Regulations (HMR) of the Pipeline and Hazardous Materials Safety Administration (PHMSA) of the U.S. Department of Transportation (USDOT) provided the answers I sought.

Using the identification number on the placard I was able to determine the shipping description from the Hazardous Materials Table at 49 CFR 172.101:

UN2304, Naphthalene, molten, 4.1, packing group III.

It’s hazard class/division is 4.1 which is designated as Flammable Solid. It would appear that we have a solid, but a cargo tank – as defined at 49 CFR 171.8 – is intended primarily for the carriage of liquids or gases. Apparently, a molten material fills that middle ground between a solid (and thus the Division 4.1) and a liquid (and thus the cargo tank).

The special provision codes in column 7 of the Hazardous Materials Table (IB1, T1, TP3) apply to the transport of this HazMat in an intermediate bulk container (IBC), or portable tank, respectively; and thus are not applicable to the transport of UN2304 in a cargo tank.

Read: The Meaning of the Symbols in Column 7 of the Hazardous Materials Table

Column 8 of the Hazardous Materials Table references the applicable section of Part 173 to identify the authorized packaging for the HazMat.

- Column 8A for the Limited Quantity Exception.

- Column 8B for a non-bulk packaging

- Column 8C for a bulk packaging

Read: What is a Bulk Packaging?

Read: Authorized Packaging in Column 8 of the Hazardous Materials Table

The reference in column 8C for UN2304 is 241, therefore: 49 CFR 173.241 – Bulk packagings for certain low hazard liquid and solid materials. Here again we see how molten naphthalene is managed as both a liquid and a solid. Authorized cargo tanks for this HazMat are identified in subparagraph (b):

- DOT specification cargo tank motor vehicles: MC 300, MC 301, MC 302, MC 303, MC 304, MC 305, MC 306, MC 307, MC 310, MC 311, MC 312, MC 330, MC 331, DOT 406, DOT 407, and DOT 412.

- Non-DOT specification cargo tank motor vehicles suitable for transport of liquids.

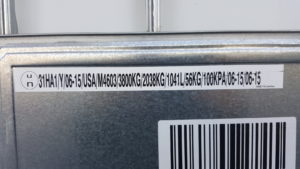

That last point is interesting as it means that a DOT specification packaging is not mandated for the transport of UN2304, Naphthalene, molten in a cargo tank! As this encounter took place at freeway speeds, I was not able to determine if it was a DOT specification cargo tank and if so, what type.

Since its transport is in a bulk packaging, the cargo tank must display the applicable placard for the hazard class or division of the HazMat, and that is clearly the case here. While only two sides of the cargo tank are visible, I’m going to assume that the placard is visible on all four sides of the cargo tank as required.

The identification number for the HazMat: UN2304 minus the “UN”, is visible on the placard. Despite its display on the placard it is actually a marking and is required by 49 CFR 172. 302(a)(1).

The display of the HOT marking – yes, I know it looks like a placard but it actually a marking – must be displayed on two opposing sides of a bulk packaging containing an elevated temperature material (49 CFR 172.325). It appears in this case more than the required number of HOT markings was used since it’s visible on in these photos on both the back and right side of the cargo tank. I will assume that the HOT marking is also displayed on the two unseen sides of the cargo tank making it visible on all four sides of the cargo tank.

Read: What is an Elevated Temperature Material?

Read: Q&A: How Must I Display the HOT Marking and the Identification Number on a Cargo Tank?

Read: Additional Description on a Shipping Paper for Elevated Temperature Material

You can tell a lot about the hazardous materials transported in our midst if you know how to read the hazard communication methods: placards, labels, markings, and shipping papers; and know how to use the Hazardous Materials Regulations of PHMSA/USDOT.

I can help you to read the hazard communication methods and learn what they mean to you. You must know this for the hazardous materials you work with every day. Contact me to schedule the HazMat Employee training required by PHMSA/USDOT regulations.