Question:

I am the carrier for an asbestos waste that has been removed from schools, businesses, and residences. Is it subject to PHMSA/USDOT regulations as a hazardous material (HazMat) when transported? Please help!

Answer:

Asbestos waste may be a hazardous material according to PHMSA/USDOT regulations if it is friable (i.e. able to be reduced to powder by hand pressure).

- Neither “asbestos”, “friable”, nor “non-friable” is defined by PHMSA/USDOT in its section of the regulations dedicated to definitions (49 CFR 171.8).

- However, what PHMSA/USDOT considers applicable to its use of the term “asbestos” is found in the packing instructions referenced in column 8 of the Hazardous Materials Table (see below).

- The term “non-friable” is explained in special provision 156 of column 7 of the Hazardous Materials Table (see below).

- Asbestos is identified as the following proper shipping names in column 2 of the Hazardous Materials Table:

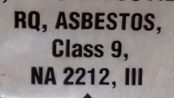

- NA2212, Asbestos, 9, III

- UN2212, Asbestos, amphibole amosite, tremolite, actinolite, anthophyllite, or crocidolite, 9, II

- UN2590, Asbestos, chrysotile, 9, III

- UN2212 & UN2590 are both more likely to be used for international transportation, whereas NA2212 is the preferred shipping description for asbestos when shipped within the U.S.

- Each of the above shipping descriptions have the special provision code of 156 in column 7 of the Hazardous Materials Table. It refers to PHMSA/USDOT’s explanation of a non-friable form of asbestos:

Asbestos that is immersed or fixed in a natural or artificial binder material, such as cement, plastic, asphalt, resins or mineral ore, or contained in manufactured products is not subject to the requirements of this subchapter.

- Column 8A of the Hazardous Materials Table indicates the packaging exceptions available for asbestos such as the Limited Quantity exception for packages of no more than 66 lbs each.

- Packaging instructions for NA2212, Asbestos can be found at 49 CFR 173.216 for a non-bulk packaging and 49 CFR 173.240 for a bulk packaging. In either section of the regulations, asbestos may be packaged as follows:

- Must follow the general packing requirements, i.e. no HazMat residue on the outside of the container, container in good condition, &etc.

- DOT specification packaging is not required.

- Asbestos must be offered for transportation and transported in rigid, leak-tight packagings, such as metal, plastic or fiber drums, portable tanks, hopper-type rail cars, or hopper-type motor vehicles.

- OR…

- Bags or other non-rigid packagings in closed freight containers, motor vehicles, or rail cars that are loaded by and for the exclusive use of the consignor and unloaded by the consignee.

- AND…

- Bags or other non-rigid packagings which are dust and sift proof must be placed in rigid outer packagings or closed freight containers.

- Asbestos is identified in Appendix A, Table 1 of the Hazardous Materials Table as a Hazardous Substance. It is a Reportable Quantity (RQ) of a hazardous substance if it is contained in a single packaging in a quantity of one (1) pound or more.

- However, The RQ for asbestos is limited to friable forms only.

- A non-friable form of asbestos can not be a Hazardous Substance.

- Non-friable asbestos is not identified in Appendix B of 49 CFR 172.102 as a marine pollutant.

- Non-friable asbestos is not a hazardous waste per the regulations of the USEPA.

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services, Inc. 815.821.1550 |

Summary: