A question. May 11, 2018:

Mr. Stoehr,

My name is <<Redacted>>, and let me start by telling you that I have been enjoying your blogs and various compliance articles for years now. I stumbled across your page years ago searching for some RCRA info and I’ve had it bookmarked ever since. I’ve never taken one of your classes, but your articles are some of the best I’ve ever seen. You have a real talent for writing, and you make complex regulatory content very digestible. Thank you for all that you do.

I have a question for you, and before I ask it, I’ll understand if you can’t just answer it outright. If there’s a fee involved, I’m more than happy to pay it. Your knowledge and time are worth money.

Now on to my question:

I had a customer recently ask if there are any DOT rules that prohibit putting the ERG# in the full DOT shipping name, and I told him that based on my understanding, the rules in 49 CFR 172.202 don’t prevent you from including additional information (like the ERG number), as long as it appears after the USDOT Description in its proper sequence. I was discussing this with a colleague of mine and he told me that he thought IATA regulations actually require the ERG in the shipping name. I don’t have a copy of the IATA rules, but I’d like to have this assertion confirmed (just for my own academic curiosity). I don’t work in the IATA sphere at all, but I’d like to at least get that question put to bed.

Thanks for your time and let me know if this is something you can answer.

Me: *BLUSH* and a reply on May 14, 2018:

I have an answer for you.

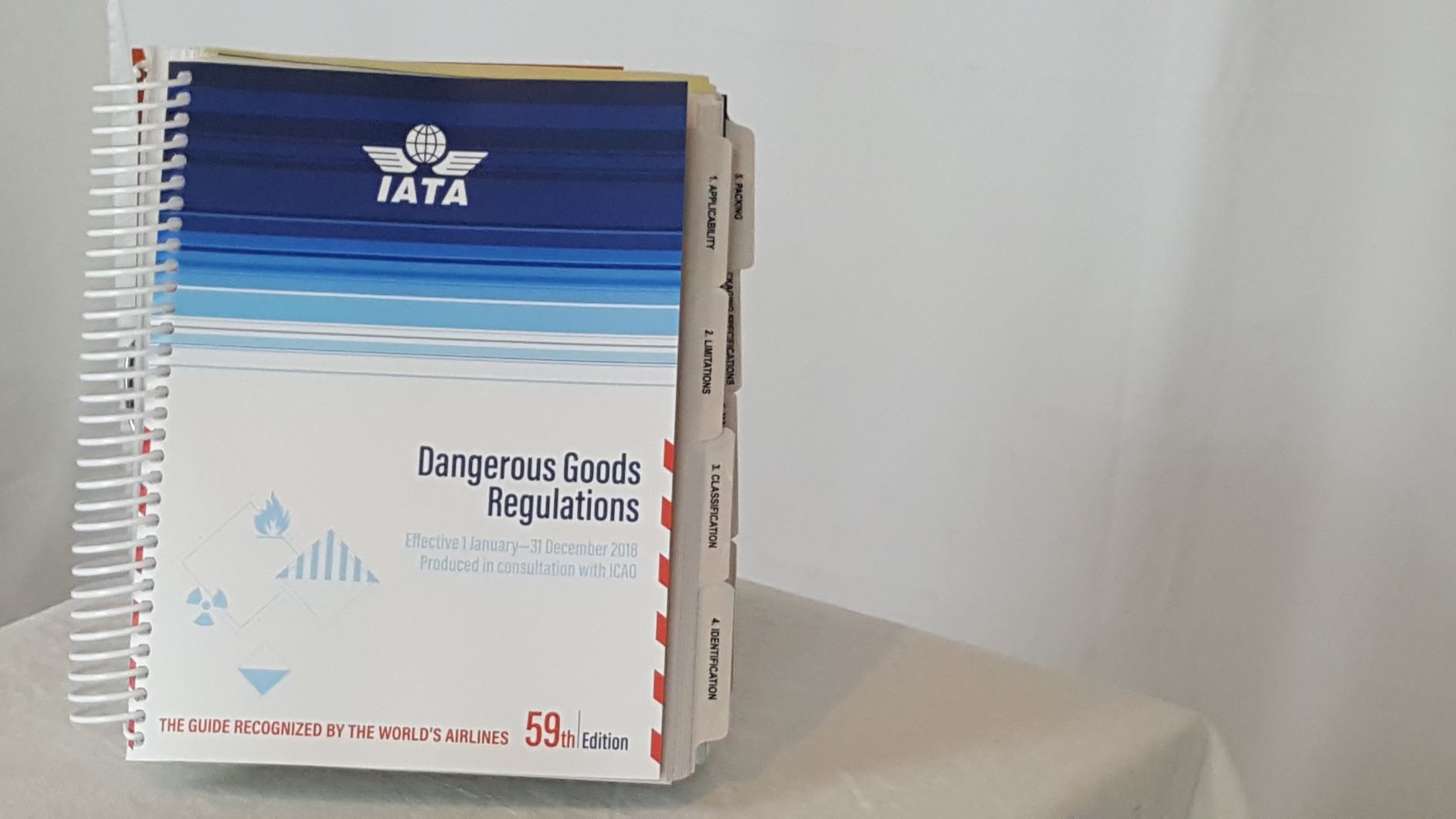

- There is nothing in the IATA Dangerous Goods Regulations that mandates the inclusion of the ERG # with the shipping description on the Shipper’s Declaration for Dangerous Goods.

- As a matter of fact, none of the emergency information required by USDOT/PHMSA is required by IATA. However, per USDOT state variation USG-12, the emergency phone number and emergency information is required for any shipment of HazMat transported from, to, or through the U.S.

- FYI: State (i.e., a country like Brazil or China) and operator variations are included in Section 2 of the IATA Dangerous Goods Regulations. These variations must be complied with and are subject to enforcement by USDOT just like the rest of the Dangerous Goods Regulations.

- IATA does allow for additional information in the description (like emergency information) if it does not detract from the communication of the hazard.

I hope this helps.

Please contact me with any other questions.

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services, Inc. 815.821.1550 |

That seemed to do it (05.14.18):

Thank you sir! You’ve been most helpful!

Thanks again for what you do. Like I said before, your website and blog are the absolute best there is.