A question from a concerned truck driver (01.10.18):

I drive lube truck and carry 600 gal go new oil and 400 gal used oil in <<state>> and surrounding states my company told me to remove placards saying not needed. I am questioning them and can’t find answer if I am legal.

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services, Inc. 815.821.1550 |

My answer (01.10.18):

Thank you for contacting me. I will try to answer your question below.

- I cannot be certain without viewing the safety data sheet (SDS) or some other technical data, but it is unlikely that oil – new or used – will meet the definition of a hazardous material per USDOT regulations.

- If not a HazMat the display of USDOT placards is not required.

I hope that answers your question. Please don’t hesitate to contact me with any other questions.

Conclusion:

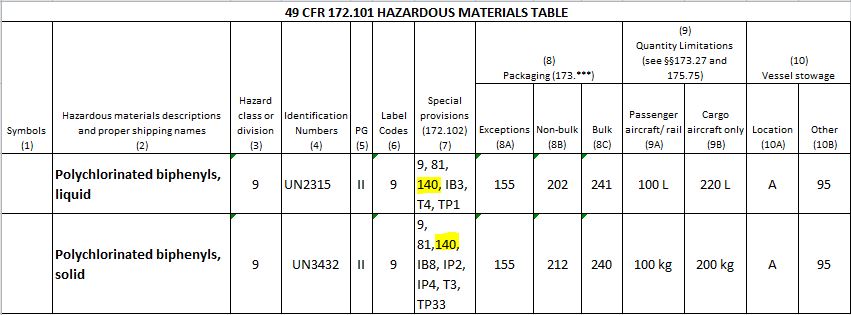

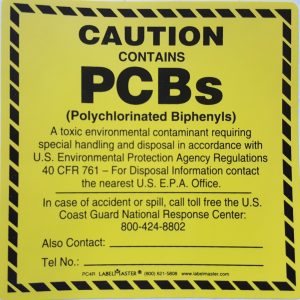

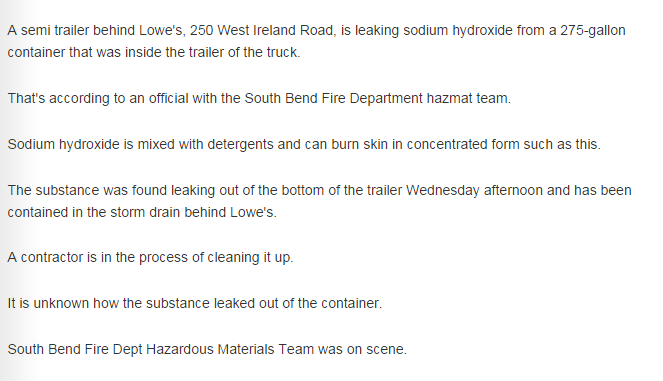

Easy but illustrating a very common issue in the regulated – or not regulated – community. Before you can begin to consider the regulations applicable to the transportation of a hazardous material: hazard communication, packaging, training, load securement & segregation, & more; you must classify the article or substance according to the USDOT/PHMSA’s definition of a hazardous material. No hazardous material, no Hazardous Materials Regulations.

It’s possible you transport or offer for transport both HazMat and non-HazMat. My training and consulting services can help you to identify the difference.