From a past attendee of one of my Training Seminars – now defunct – on May 19, 2015:

Dan,

I seem to recall hearing that the EPA does not like the telescoping boxes for used lamps. I can only assume this is because the container may not meet the definition of “closed.” Has EPA given any written interpretation on this? Or better yet, do you know of a better method for storing 8-ft used fluorescent lamps that is better than standard 8-ft lamp boxes, is easier to access, and meets the closure rule?

Thanks,

My reply later that same day:

I have not heard anything like that from USEPA or any state. I confess, though that I am not certain of what you mean by “telescoping boxes”. USEPA regulations at 40 CFR 273.13(d) read as follows (emphasis mine):

(d) Lamps. A small quantity handler of universal waste must manage lamps in a way that prevents releases of any universal waste or component of a universal waste to the environment, as follows:

(1) A small quantity handler of universal waste must contain any lamp in containers or packages that are structurally sound, adequate to prevent breakage, and compatible with the contents of the lamps. Such containers and packages must remain closed and must lack evidence of leakage, spillage or damage that could cause leakage under reasonably foreseeable conditions.

(2) A small quantity handler of universal waste must immediately clean up and place in a container any lamp that is broken and must place in a container any lamp that shows evidence of breakage, leakage, or damage that could cause the release of mercury or other hazardous constituents to the environment. Containers must be closed, structurally sound, compatible with the contents of the lamps and must lack evidence of leakage, spillage or damage that could cause leakage or releases of mercury or other hazardous constituents to the environment under reasonably foreseeable conditions.

My inquirer provides additional information (May 20, 2015):

My inquirer provides additional information (May 20, 2015):

Dan,

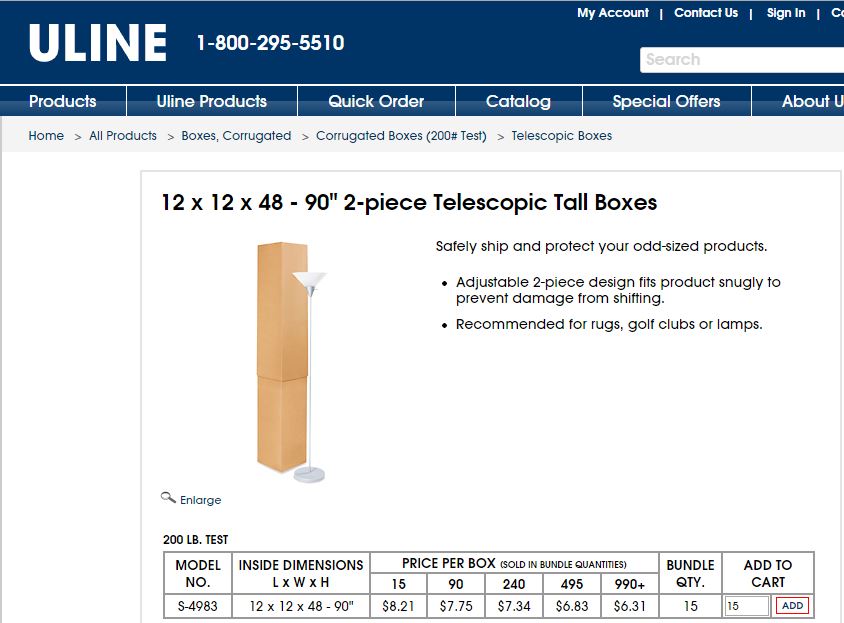

Thanks for the response. A telescoping box is essentially 2 boxes that interlock onto each other and adjust to the length of the item stored. For an example see following link:

May 20, 2015, I provide the best answer I could:

OK. I took a look at the telescoping boxes, and it appears OK to me. I think you are OK as long as you comply with 40 CFR 273.13(d) unless an inspector tells you different.

It took him a while to reply, but on June 24, 2015:

Dan,

Yes that’s fine. Another question…

Well, that other question will be used in an article to follow later.

Though Handlers of universal waste are not require to “train” their employees the same way they are to train hazardous waste personnel, it is not a bad idea to provide some type of training on how to handler universal waste and what to do in the event of a spill or other emergency. This is what I do in my Onsite Training for Hazardous Waste Personnel.

Contact me with any questions you may have about the generation, identification, management, and disposal of hazardous waste Daniels Training Services 815.821.1550 |