40 CFR 261.4(a)(17) The Mineral Processing Secondary Materials Being Recycled Exclusion From Regulation as a Solid Waste

The Hazardous Waste Personnel Training Requirement for a Small Quantity Generator of Hazardous Waste

The regulatory requirement for training employees who work with or around hazardous waste or may respond to a hazardous waste emergency depends upon your hazardous waste generator status (take this quick survey to determine your hazardous waste generator status). A brief summary of the applicable training requirements:

- A large quantity generator of hazardous waste must train all facility personnel within 6 months of employment and annually thereafter [40 CFR 262.17(a)(7)].

- A conditionally exempt small quantity generator of hazardous waste has no training requirement [§261.14].

- A small quantity generator of hazardous waste is not specifically required to provide training to its facility personnel. However, training may be necessary in order to comply with the applicable regulations [§262.16(b)(9)(iii)].

40 CFR 262.16(b)(9)(iii) reads:

The small quantity generator must ensure that all employees are thoroughly familiar with proper waste handling and emergency procedures, relevant to their responsibilities during normal facility operations and emergencies;

The regulations do not specify how the generator must “ensure” that all of their employees are “thoroughly familiar” with the relevant procedures for handling waste and for responding to emergencies. Options include:

- On-the-job experience,

- Prior work experience,

- Education,

- Signs and labels to communicate information,

- Work Instructions or SOP’s that provide relevant guidance,

- And training.

While not required it is assumed by the US EPA and state agencies that training will play a role – if not THE role – in complying with §262.16(b)(9)(iii) (RO11779).

While not required it is assumed by the US EPA and state agencies that training will play a role – if not THE role – in complying with §262.16(b)(9)(iii) (RO11779).

Note: As of the effective date of the Generator Improvements Rule on May 30, 2017 the Federal regulations referenced in this article changed from their previous location in the Code of Federal Regulations. The regulations of your state may still refer to the original location of the Federal regulations at 40 CFR 262.34(d)(5)(iii). There have been no other changes to the regulations for the training requirements of an SQG other than their location in the CFR. |

It is also important to note that this regulation falls within the larger framework of an SQG’s responsibility to respond to an emergency, sometimes known as the Small Quantity Generator’s Basic Plan. Therefore, your training must address the emergency response procedures your employees need to know relevant to their job duties.

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services, Inc. 815.821.1550 |

Even if you determine that training is not required you and your employees will benefit from learning what regulations are applicable to their job duties and how those regulations fit into the greater regulatory structure.

What are ICR-Only Listed Hazardous Waste?

A requirement of a generator’s hazardous waste determination is to determine if their waste is listed at 40 CFR 261, Subpart D. The four lists that make up the hazardous waste listing are:

- F-List for generic industrial sources.

- K-List for specific industrial processes.

- P or U-List for unprocessed commercial chemical products.

Any solid waste that isn’t excluded elsewhere and matches the description of a hazardous waste listing is a hazardous waste and subject to full regulation under RCRA.

The US EPA uses three (3) different criteria to determine whether or not to include a process or chemical in one of the four hazardous waste listings, the three criteria are:

- The waste typically contains toxic chemicals at levels that could pose a threat to human health and the environment if improperly managed. If this criteria is the basis for listing a waste it is assigned a hazard code of T for Toxic Waste.

- The waste contains such dangerous chemicals that it could pose a threat to human health and the environment even when properly managed. These wastes are fatal to humans and animals in low doses. If this criteria is the basis for listing a waste it is assigned a hazard code of A for Acute Hazardous Waste.

- The waste typically exhibits one of the four characteristics of hazardous waste: Ignitability, Corrosivity, Reactivity, Toxicity. If this criteria is the basis for listing a waste it is assigned a hazard code according to its characteristic: Ignitable Waste (I), Corrosive Waste (C), Reactive Waste (R), Toxicity Characteristic Waste (E).

Note the following:

- The reference to “hazard code” should not be confused with “hazardous waste codes”. The “hazard code” is an indication of the US EPA’s reasoning for listing the waste. A “hazardous waste code” is assigned to all wastes determined to be hazardous (either characteristic or listed).

- A Toxic Waste (T) differs from a Toxicity Characteristic Waste (E). The Toxic Waste meets the first of the three criteria, that is it typically contains toxic chemicals that could pose a threat if improperly managed. The Toxicity Characteristic Waste exhibits the characteristic for Toxicity which is a basis for listing a waste identified in the third criteria.

- The four characteristics of hazardous waste – Ignitable, Corrosive, Reactive, & Toxic – are described in §261, Subpart C.

- A waste that is determined to be a listed hazardous waste solely because it exhibits one or more characteristics of Ignitability, Corrosivity, or Reactivity is known as an ICR-Only Listed Waste.

- There are 29 ICR-Only Listed Wastes:

Waste Code | Description | Hazard Code |

| F003 | Non-halogenated spent solvents | I |

| K044 | Wastewater treatment sludges from explosives | R |

| K045 | Spent carbon from treating explosive wastewater | R |

| K047 | Pink/red water from TNT operations | R |

| P009 | Ammonium picrate | R |

| P081 | Nitroglycerine | R |

| P112 | Tetranitromethane | R |

| U001 | Acetaldehyde | I |

| U002 | Acetone | I |

| U008 | Acrylic acid | I |

| U020 | Benzenesulfonyl chloride | C, R |

| U031 | n-Butyl alcohol | I |

| U055 | Cumene | I |

| U056 | Cyclohexane | I |

| U057 | Cyclohexanone | I |

| U092 | Dimethylamine | I |

| U096 | Cumene hydroperoxide | R |

| U110 | Di-n-propylamine | I |

| U112 | Ethyl acetate | I |

| U113 | Ethyl acrylate | I |

| U117 | Ethyl ether | I |

| U124 | Furan | I |

| U125 | Furfural | I |

| U154 | Methanol | I |

| U161 | Methyl isobutyl ketone | I |

| U186 | 1,3-Pentadiene | I |

| U189 | Sulfur phosphide | R |

| U213 | Tetrahydrofuran | I |

| U239 | Xylene | I |

- A waste that matches the description of an ICR-Only Listed Waste is not assigned the listed hazardous waste code if it does not exhibit the applicable hazardous waste characteristic at the point of generation. Example: Spent acetone used as a solvent matches the listing description for F003 (non-halogenated spent solvent). F003 has a Hazard Code of I for the characteristic of Ignitability. If the spent solvent does not exhibit the characteristic of Ignitability at the point of generation, then the F003 hazardous waste code would not apply.

- Additionally, if an ICR-Only Listed Waste is mixed with a solid waste the resulting mixture does not retain the listed hazardous waste code if the mixture does not exhibit the applicable hazardous waste characteristic [40 CFR 261.3(g)(2)(i)]. Example: Spent acetone used as a solvent matches the listing description for F003 (non-halogenated spent solvent). F003 has a Hazard Code of I for the characteristic of Ignitability. If the spent solvent is mixed with a non-hazardous waste so that the resulting mixture does not exhibit the characteristic of Ignitability, then the F003 hazardous waste code would not apply.

- Read more about F-Listed Spent Solvents.

The fact that an ICR-Only Listed Waste retains its listed hazardous waste code only if the applicable characteristic hazardous waste is exhibited may play a crucial role in your hazardous waste determination. This then will impact your hazardous waste generator status and all subsequent regulations with which you must comply. Make certain you have conducted the hazardous waste determination correctly and documented the outcome. As always check with your state regulatory agency on issues such as these and please don’t hesitate to contact me with any questions.

Generator Treatment of Hazardous Waste in Ohio

In an earlier article I summarized the US EPA regulations regarding onsite treatment of hazardous waste by a generator. The Ohio EPA have their own regulations pertaining to this subject; they largely follow the US EPA but with some important differences.

Treatment is defined in the Ohio Administrative Code at 3745-50-10(A) as any method, technique or process – including neutralization – designed to change the physical, chemical or biological character or composition of any hazardous waste to:

- Neutralize the waste.

- Recover energy or material resources from the waste.

- Render the waste nonhazardous or less hazardous.

- Make the waste safer to transport, store or dispose.

- Make the waste easier to recover or store.

- Reduce the volume of waste.

Pursuant to 3745-52-10(C) of the OAC a generator is allowed to treat their own hazardous waste without a permit provided they comply with 3745-52-34. These are the standard management requirements for the accumulation of hazardous waste; they include: labeling, closed container, onsite accumulation time limit, training, inspections, etc. 3745-52-10(C) does not specify a generator status, therefore it applies to all generators of hazardous waste: Large Quantity Generator, Small Quantity Generator, & Conditionally Exempt Small Quantity Generator. If treating hazardous waste, an LQG or SQG must comply with the regulations applicable to their generator status. Where Ohio differs from the US EPA is that a CESQG that treats its waste must comply with the regulations of an LQG.

Acceptable forms of onsite treatment for a hazardous waste generator in Ohio include, but are not limited to:

- Stabilization: Mixing a characteristic hazardous waste (D008 Toxicity for Lead) with cement to stabilize the lead.

- Wastewater Treatment: A variety of methods may be used to remove a hazardous constituent from a wastestream if the wastewater treatment unit and its discharge is permitted under the Clean Water Act.

- Neutralization: Mixing an acidic waste (D002 Corrosivity) with an alkaline material to neutralize it, or vice versa.

- Polymerization: A resin (D001 Ignitable) may be mixed with its reactant to cause a polymerization reaction creating a solid nonhazardous waste.

- Evaporation: Evaporation of an aqueous (water-based) waste that does not contain volatile organic compounds. Any release of a hazardous waste, such as VOC’s, to the air is disposal and not allowed without a permit.

The following must also be considered before conducting hazardous waste treatment without a permit in Ohio:

- The waste must be generated onsite.

- Acceptable units for onsite treatment of hazardous waste are limited to: Containers, Tanks, and Containment Buildings.

- The Federal RCRA air emission standards may apply, refer to: 40 CFR 265, Subpart AA, BB, or CC.

- Thermal treatment (incineration) is not allowed. This includes treatment at ambient temperatures, eg. leaving solvent-soaked rags to dry. Refer to the description of Evaporation above.

- The closed container requirements do not apply to a hazardous waste undergoing treatment in a container.

The Ohio land disposal restrictions of 3745-270 present an additional treatment standard – beyond the determination of hazardous or non-hazardous – that must be met before the waste may be land disposed. This means that if you intend to treat your hazardous waste to make it non-hazardous you must also decide if your treatment will meet the LDR.

- If not treated to meet the LDR: Then the waste will have to be treated to meet the LDR’s before land disposal.

- If treated to meet the LDR: Then you must comply with the requirements of 3745-270, which include:

- Develop a written Waste Analysis Plan [3745-270-07(A)(5)].

- Comply with the notification and certification requirements [3745-270-07(A)].

This information is based on the regulations of the Ohio EPA, the Federal regulations and those of your State will differ. Check with your State for its interpretation of these regulations.

Additional information is available from the Ohio EPA: DHWM Guidance Document – Generator Treatment.

As always, please don’t hesitate to contact me if you have any questions about the RCRA regulations (Federal or State) or those of the US DOT for the transportation of hazardous materials.

New Haven Company Will Pay Penalty for Hazardous Waste Violations

Release Date: 11/26/2012

Contact Information: David Deegan, (617) 918-1017

(Boston, Mass. – Nov. 26, 2012) – A New Haven, Conn. company that makes door hardware has agreed to pay $39,705 to settle EPA’s claims that it violated state and federal hazardous waste laws.

The Sargent Manufacturing Company violated state hazardous waste laws as well as the federal Resource Conservation and Recovery Act (RCRA). These laws are designed to help protect public health and the environment by promoting the proper management of hazardous wastes.

The complaint grew out of an inspection of the facility in March 2011 by EPA. Sargent violated RCRA by failing to: have an adequate hazardous waste training program, close containers of hazardous waste, maintain adequate aisle space between containers of hazardous waste, mark containers with the date that accumulation of hazardous waste began, update and submit a revised contingency plan to local authorities, and otherwise manage hazardous waste in accordance with the requirements.

Sargent’s failure to have an adequate hazardous waste training program increased the likelihood that wastes generated may not be properly managed and that Sargent personnel may not be able to adequately coordinate all emergency response measures in the event of emergency.

After the inspection, Sargent brought its facility into compliance with state and federal waste management laws.

More information: Enforcing hazardous waste laws in New England(http://www.epa.gov/region1/enforcement/waste/index.html)

EBV Explosives Environmental Company to Pay $580,135 Penalty for Air, Hazardous Waste Violations at Carthage, Mo.

Release Date: 12/19/2012

Contact Information: Ben Washburn, 913-551-7364, washburn.ben@epa.gov

Environmental News

FOR IMMEDIATE RELEASE

(Lenexa, Kan., Dec. 19, 2012) – EBV Explosives Environmental Company, doing business as General Dynamics Ordnance and Tactical Systems – Munitions Services, has agreed to pay a $580,135 civil penalty to settle alleged violations of the Clean Air Act and Resource Conservation and Recovery Act (RCRA) at its facility in Carthage, Mo.

In February 2011, EBV sent a letter to EPA that informed the Agency that stack tests conducted in October 2010 indicated that the hydrogen chloride emission rate at the facility was above permitted levels.

Alleged violations at the facility include operation of a thermal treatment unit without obtaining a valid permit, in violation of the Missouri State Implementation Plan and the Clean Air Act; operating in noncompliance with its Hazardous Waste Management Facility permit from the Missouri Department of Natural Resources on several occasions by exceeding its permitted emission limits for dioxins and furans, hydrogen chloride and chlorine gas, and particulate matter and its permitted operating parameters for stack flow rate; and failure to operate monitors that record the operating parameters and conditions used to verify compliance with the permit.

EPA and EBV entered into an Administrative Order on Consent under the Clean Air Act in January 2012, which required EBV to install equipment to reduce the facility’s hydrogen chloride emissions below permitted levels. Since the order was issued, EBV installed a scrubber, made associated changes to the Propellant Thermal Treatment Unit, and completed stack testing to demonstrate that the facility’s emissions are below permitted levels.

“EPA’s enforcement of these important environmental laws has caused EBV to cut particulate emissions by approximately 1,240 pounds per year and hydrogen chloride and chlorine gas emissions by 200,000 pounds per year,” said EPA Region 7 Administrator Karl Brooks. “EBV’s commendable step to install and operate new technology to prevent excess emissions of these chemicals will mean cleaner air and better health for Carthage area residents.”

As a result of the settlement, EBV has agreed to provide EPA with documentation on a monthly basis that demonstrates it is in full compliance with its RCRA permit.

40 CFR 261.4(a)(14) – The Shredded Circuit Board Exemption From the Definition of Solid Waste

Management of Empty Containers in Texas

As a state with an authorized hazardous waste program, Texas has its own regulations for the management of hazardous waste enforced by the Texas Commission on Environmental Quality (TCEQ). In addition, Subtitle D of the Resource Conservation and Recovery Act (RCRA) empowered the states to manage non-hazardous waste as they see fit with minimal oversight from the US EPA. For better or worse, Texas has exercised this authority to create extensive regulations pertaining to non-hazardous waste generated at industrial facilities (Industrial Solid Waste). TCEQ identifies an Industrial Solid Waste as:

As a state with an authorized hazardous waste program, Texas has its own regulations for the management of hazardous waste enforced by the Texas Commission on Environmental Quality (TCEQ). In addition, Subtitle D of the Resource Conservation and Recovery Act (RCRA) empowered the states to manage non-hazardous waste as they see fit with minimal oversight from the US EPA. For better or worse, Texas has exercised this authority to create extensive regulations pertaining to non-hazardous waste generated at industrial facilities (Industrial Solid Waste). TCEQ identifies an Industrial Solid Waste as:

Industrial Solid Wastes are not hazardous waste and result from (or are incidental to) operations of industry, manufacturing, mining, or agriculture – for example, wastes from power generation plants, manufacturing facilities, and laboratories serving an industry.

Industrial Solid Waste are further broken down into three classes:

- Class 1 – toxic, corrosive, flammable, a strong sensitizer or irritant, may generate sudden pressure, or may pose a substantial potential danger.

- Class 2 – cannot be described as a Class 1 or Class 3.

- Class 3 – inert, essentially insoluble, and not readily decomposable.

With that very brief introduction (refer to the TCEQ guidance document for more information: Guidelines for the Classification and Coding of Industrial and Hazardous Wastes), I’ll proceed to the point of this article: The Management of Empty Containers in Texas.

We start with a container that meets the definition (both US EPA & TCEQ regulations agree) of RCRA Empty. If RCRA Empty, a container and its residue are no longer regulated as a hazardous waste. It is, however, regulated by the TCEQ as an Industrial Solid Waste. As the generator, you must determine if it is a Class 1 or Class 2 Industrial Solid Waste and manage accordingly.

A RCRA Empty container is a Class 1 Industrial Solid Waste if its capacity is >5 gallons and it previously stored a:

- Hazardous Substance as defined at 40 CFR Part 302,

- Hazardous Waste,

- Class 1 Industrial Solid Waste, and/or

- a material that would be classified as a hazardous waste or Class 1 Industrial Solid Waste if disposed.

A RCRA Empty container is a Class 2 Industrial Solid Waste if:

- Its capacity is ≤5 gallons, or

- it previously stored a Class 2 Industrial Solid Waste.

You may classify a Class 1 empty container as a Class 2 under the two following options:

Option 1: Both of the following conditions are true:

- The residue is completely removed by one of the following:

- Triple rinsing with a solvent capable of removing the waste,

- Hydro-blasting, or

- by other methods.

- The container is crushed, punctured, or subjected to other mechanical treatment that renders it unusable.

Option 2: The container will be recycled and all of the following are true:

- The residue is completely removed by one of the following:

- Triple rinsing with a solvent capable of removing the waste,

- Hydro-blasting, or

- by other methods.

- The container is not regulated under the Federal Insecticide, Fungicide and Rodenticide Act (FIFRA).

- The generator maintains documentation per 30 TAC 335.513 – Documentation Required, that demonstrates the container is being recycled.

- The recycling activity involves one of the following:

- shredding,

- dismantling,

- scrapping,

- melting,

- or other method that renders the container unusable.

Your onsite management, offsite disposal, recordkeeping, reporting, etc. will all depend on how much and what Class of Industrial Solid Waste you generate. Classifying your empty containers is just one small step of a long process to ensure you are in compliance with the regulations of the US EPA and the TCEQ. I recommend you to the TCEQ guidance document I linked to earlier in this article for additional guidance. Or, contact me for a free consultation on the applicable Texas regulations. You may also consider Onsite Training as a way for you and all your employees to learn the applicable regulations of the TCEQ.

Total Quantity of a Hazardous Material on a Shipping Paper

The regulations of the US Department of Transportation at 49 CFR 172.202 indicate the requirements for a hazardous materials description on a shipping paper. A hazardous waste accompanied in transportation by a Uniform Hazardous Waste Manifest is subject to the regulations of both the US DOT and the US Environmental Protection Agency at 40 CFR 262, Subpart B (or authorized State agency). The regulations of both agencies require an indication of the Total Quantity and the Number and Type of Containers/Packages when describing a Hazardous Waste/Hazardous Material on a Manifest/Shipping Paper. They differ, however, in the form this information must take and so it is up to you as the Generator/Shipper to ensure you are in compliance.

The purpose of this article is to explain the requirements of both the US EPA and the US DOT for indicating the Total Quantity of a Hazardous Material (which includes Hazardous Waste) on a Shipping Paper (which includes a Uniform Hazardous Waste Manifest). In a later article I will address the requirements for the Number and Type of Containers/Packaging.

The regulations of the US DOT at 49 CFR 172.202(a)(5) read:

Except for transportation by aircraft, the total quantity of hazardous materials covered by the description must be indicated (by mass or volume, or by activity for Class 7 materials) and must include an indication of the applicable unit of measurement, for example, ‘200 kg’ (440 pounds) or ’50 L’ (13 gallons). The following provisions also apply:

Note the following:

- The regulations for shipments of a hazardous material by air are found at §172.202(a)(6).

- Total Quantity may be indicated by mass or volume.

- Since the regulations do not indicate if a net or gross mass/volume is required for the Total Quantity, either is acceptable. Therefore, the Total Quantity may include the weight of the hazardous material packaging (net), or solely the weight of the HazMat (gross).

- Note the reference to Class 7 Radioactive materials.

- Any unit of measure is acceptable as long as one is present, unless it is one of the exceptions referenced below that do not require a Total Quantity.

- “The following provisions also apply:“, refers to the following:

- Class 1 Explosive materials.

- Hazardous materials in salvage packaging.

- Exceptions to 172.202(a)(5) for: Bulk Packages, Cylinders, & Packages with Residue.

Also, §172.202(c) includes the following regarding the Total Quantity:

- It must appear before or after, or both before and after, the hazardous materials description.

- Abbreviations may be used to express the units of measurement for the Total Quantity.

At 40 CFR 262, Subpart B the US EPA indicates the requirements for a generator of hazardous waste who offers it for transportation. §262.20(a)(1) requires a generator to prepare a Manifest, “…according to the instructions included in the appendix to this part.” The instructions for Items 11 & 12 on the Manifest (Total Quantity & Units of Measure respectively) include the following:

Item 11. Total Quantity: Enter, in designated boxes, the total quantity of waste. Round partial units to the nearest whole unit, and do not enter decimals or fractions. To the extent practical, report quantities using appropriate units of measure that will allow you to report quantities with precision. Waste quantities entered should be based on actual measurements or reasonably accurate estimates of actual quantities shipped. Container capacities are not acceptable as estimates.

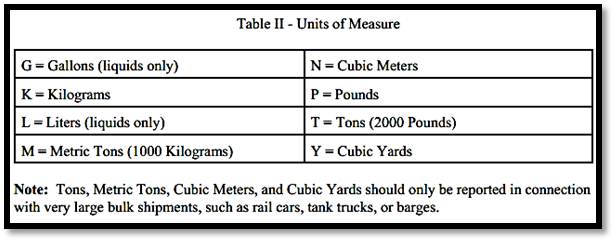

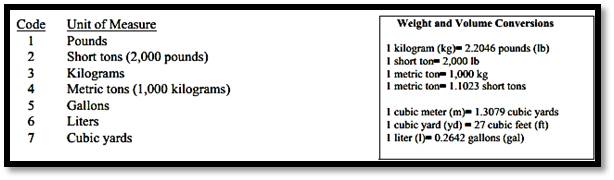

Item 12. Units of Measure (Weight/Volume): Enter, in designated boxes, the appropriate abbreviation from Table II (below) for the unit of measure.

Note the following:

- Total Quantity must be entered in Item 11 of the manifest, unit of measure in Item 12, no exceptions.

- The US EPA is much more specific in its instructions as to how it wishes the number to appear: “Round partial numbers…“

- Entering the “container capacity” or other rough estimates are not acceptable. US EPA desires an “actual measurement or reasonably accurate estimate…” of the Total Quantity.

- The US EPA instructions for the Manifest, like the US DOT in its regulations, does not specify the use of net or gross mass/volume for the Total Quantity. Therefore, the Total Quantity may include the weight of the containers, or if an accurate measurement can be made, solely the weight of the hazardous waste in the containers.

- Unlike the US DOT, the US EPA requires specific units of measure and acceptable abbreviations; refer to Table II – Units of Measure

- The US EPA goes further to recommend the use of certain units of measure (Tons, Metric Tons, & Cubic Yards) for very large bulk shipments (rail cars, tank trucks, or barges).

- Whatever unit of measure you choose, completion of the Hazardous Waste Report will be easier if you remain consistent and select a unit of measure required by the Report (see below):

So, which regulations must you comply: Those of the US DOT or those of the US EPA? Well, if shipping a hazardous material that is not a hazardous waste, then you need only follow the requirements of the US DOT. If, however, what you offer for transportation is a hazardous waste – and you are not a Conditionally Exempt Small Quantity Generator of hazardous waste – then you must comply with the regulations of both agencies (and those of your state if it has an authorized hazardous waste program).

So in sum…

At 49 CFR 172.205(a) the US DOT requires completion of the Manifest per the regulations of the US EPA for the transportation of a hazardous waste. Further, at §172.205(h), it requires the Manifest to contain all of the applicable elements of the hazardous materials description.

and…

According to 40 CFR 262.202(a)(1), you must complete the Manifest per the instructions included in the appendix to §262. Also, check with your state to see if it has any additional requirements for completion of the Manifest.

These types of questions come up in my training all the time. Sign up to attend one of my training events, or contact me with a question regarding the regulations of the US DOT or the US EPA.

Determining Your Hazardous Waste Generator Status

The determination of your hazardous waste generator status is necessary in order to identify which of the RCRA regulations (Federal & State) apply to your operations and what you must do to ensure compliance. This determination is based on the amount of non-exempt hazardous waste you generate in a calendar month.

In a future article I will address the determination of hazardous waste generator status based on the generation of acute hazardous waste and the amount of hazardous waste accumulated on-site.

Some States have their own criteria for determining hazardous waste generator status, do not recognize all three of the US EPA status, and/or have added an additional status level to the base three of the US EPA; so be sure to check with your State. However, the three categories of hazardous waste generator status identified by the US EPA and most States are:

- Large Quantity Generator of hazardous waste (LQG).

- Small Quantity Generator of hazardous waste (SQG).

- Conditionally Exempt Small Quantity Generator of hazardous waste (CESQG). In some states this same status is referred to as: Very Small Quantity Generator or VSQG.

Take this survey to determine your generator status, but before you do, read below to ensure you understand properly the terms used in making this determination.

“Generates”: The determination is based solely on the amount of hazardous waste generated. It does not include hazardous waste that was shipped off-site for disposal, accumulated onsite, or the amount moved from one accumulation area to another within the same facility. This includes the transfer of hazardous waste from a Satellite Accumulation Area to a Central Accumulation Area (aka: 90/180 Day Accumulation Area). Read here to learn how to avoid double-counting your hazardous waste.

“Hazardous Waste”: You need only account for hazardous waste. Other forms of waste that are non-hazardous (not listed or characteristic hazardous waste), exempt from regulation as a solid waste or hazardous waste, or perhaps are a “de-regulated” form of hazardous waste: Universal Waste or Used Oil; are not counted towards the determination threshold. This article has more information about the types of waste not counted for the hazardous waste determination.

“Calendar Month”: The determination is based on a calendar month, not a 30 day rolling time period, or an average taken over a year, or anything else. As a generator of hazardous waste, you must make your determination anew for each month of the year. Changes to your generator status on a month-to-month basis are addressed by the US EPA as Episodic Generator Status.

“You”: The determination is limited to the hazardous waste generated by you at your site. A generator site is a fixed geographic location and may include contiguous parcels under the same ownership instead of a single property. There are some gray areas where another person may generate a hazardous waste at your site, this is known as Co-Generator Status. Read this earlier article for an explanation of Co-Generator Status.

Do your homework and prepare yourself prior to conducting your hazardous waste determination. If you have already determined your status, I suggest you check it again periodically – even monthly – to ensure there has not been a change in your status. As always, please don’t hesitate to contact me with any questions.