Around the Fourth of July Holiday in 2016 I sent a “What’s up?” email to several past contacts. One of them responded with this question:

If you are on holiday I hope your enjoying your 4th of July as well.

I do have one question. Are you familiar with “markings” on ibc one way containers. I call them stringers.

It starts of with the type of container/Y/Date/…….some specs, and date tested.

Then to the far right of container will be a smaller marking from a reputable company that has retested the container.

For example M6148 L 3/15. a “L” or “General Maintenance” and the date of the re-test.

According to what I know, if the original “markings” are not clear or damaged from abuse that makes that container ineligible for haz mat shipping.

BUT…..what if the secondary marking to the right, from a reputable company, is legible showing a current “L” retest that is current (2.5yrs) window…..would that make the container legal for shipping haz mat.

Call me if my inquiry makes no sense.

|

Daniels Training Services 815.821.1550 |

It took awhile, but almost two months later I responded:

I have an answer for you!

First of all, I apologize for my delayed response. I’ve been busy providing Onsite Training and Webinar Training plus performing Consulting Services. Questions like yours I research and reply to when I have the time.

The answer to your question is quite simple:

- Per 49 CFR 173.35 General requirements for HazMat in IBCs, it is the responsibility of the shipper to ensure the markings required by 49 CFR 178.703 are present on an IBC before transportation.

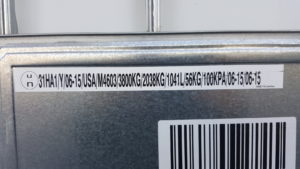

49 CFR 178.703 Marking of IBCs, requires the manufacturer of an IBC to mark it in a durable and clearly visible manner in the following sequence (49 CFR 178.703(a)):

- United Nations symbol (UN).

- Code number designating IBC type.

- Capital letter (X, Y, or Z) indicating performance standard.

- Month (designated numerically) and year (last two digits) of manufacture.

- Country authorizing the allocation of the mark. e.g. USA indicates IBC is manufactured and marked in the U.S. in compliance with the USDOT Hazardous Material Regulations.

- The name and address or symbol of the manufacturer of the IBC.

- The stacking test load in Kg. ‘0’ = not designed for stacking.

- The maximum permissible gross mass of the IBC and HazMat in Kg.

- Additional markings are required at 49 CFR 178.703(b)(1) for rigid plastic & composite IBCs.

- No sequence is specified.

- Markings must be near the required markings (see above) and readily accessible for inspection.

- Where units of measure are used, metric unit (i.e. Kg or L) must be included in marking.

- Rated capacity in L of water.

- Tare mass in Kg.

- Gauge test pressure in kPa.

- Date of last leakproofness test, if applicable (month and year).

- Date of last inspection (month and year).

- General requirements:

- Required markings:

Answer:

The presence of a marking indicating the date of the last leakproofness test or inspection (name of company performing test or inspection and country where test or inspection took place is not required) does not remove the need for the IBC to be marked with its date of manufacture (month and year).

I hope this answers your question. I have more information I learned during my research that I am willing to share with you.

Once again, I apologize for my tardiness.

Please don’t hesitate to contact me with any questions.

It took him almost a month to respond to all of that information, but when he did it was with more questions!

It took him almost a month to respond to all of that information, but when he did it was with more questions!Daniel,

Thank you.

If I may i have another question.

We have a carrier we like using for hot shots.

We will put 6 totes on his truck. 4 with 1760 ID and 2 with 1824 ID. Both are Corrosive. We offer him placards for both ID’s. He does not have means to attach placards to each side of his flatbed. The sides are no issue. We also load equipment along with totes. He will attach the placards on a 500g empty tank at the rear of his truck and also on the front end of his flatbed. Is this acceptable, or legal? So if you can imagine his flatbed with 6 totes, each tote having ID’s on them, and equipment such as tanks, pumps , etc……his flatbed placarded on each side, but the ends placarded on the tanks.

Thanks again.

My reply:

I will research and get you an answer.

|

Contact me with any questions you may have about the transportation of hazardous materials by air, highway, vessel, or rail International and Domestic Daniels Training Services 815.821.1550 |

As a teaser, I provided him with the following:

I will get you an answer on the above.

In the mean time…I wrote the following article for my blog based on the research I performed in answering your earlier question. I hope they provide helpful information.

- The General Specification Marking Requirements for Packagings

- Specification Packaging Requirements for IBCs

- Additional Requirements for Specification Packaging Markings on IBCs

I hope this helps.

Finally, a few weeks later – and 3 1/2 months from his first question – I answered his latest query:

I will attempt to answer your question. Please see below:

- 49 CFR 172.504(a) requires placards on each side and each end of a vehicle required to display placards.

- 49 CFR 172.516(a) requires placards to be clearly visible from the direction it faces, except when facing the tractor of a tractor/trailer combination.

- The requirement of 49 CFR 172.516(a) may be met by the placards displayed on the vehicle or on the load itself if the display meets all of the requirements, i.e., readily visible, on background on contrasting color, clear of appurtenances and devices, &etc. This PHMSA interpretation letter addresses this issue: 10-0075.

In sum, it is acceptable if the placards and identification numbers are mounted on the load and not on the vehicle as long as they are visible. Without a picture I cannot be certain but I have a question about the visibility of the placard on the front tote on the flatbed. Is it visible to the front? Is the motive power separate from the trailer, i.e. a tractor/trailer combination? Or, is it a straight truck?

I hope this helps.

If you have a question and want a free answer, don’t hesitate to contact me. It may take me some time but I will respond! If you want an answer faster, you’ll have to pay. My consulting services will give you the answer you need in a timely manner so that you can continue with your business without fear of fines or incidents. Whatever your question may be about the transport of hazardous materials or the management of waste (hazardous, universal, used oil, or non-hazardous), don’t hesitate to contact me.